Advanced Ultrasonic Testing

Pro-Surve Technical Services, LLC. (PSTS) delivers precise, non-destructive material evaluation through advanced ultrasonic testing methods.

Our services support critical industries, including oil and gas, power generation, and manufacturing, by detecting internal flaws, measuring wall thickness, and mapping corrosion without damaging components.

Our technicians apply ultrasonic techniques tailored to the specific inspection requirements, material type, and geometry. Whether assessing weld quality or evaluating asset condition, Pro-Surve provides reliable data that supports informed maintenance and compliance decisions.

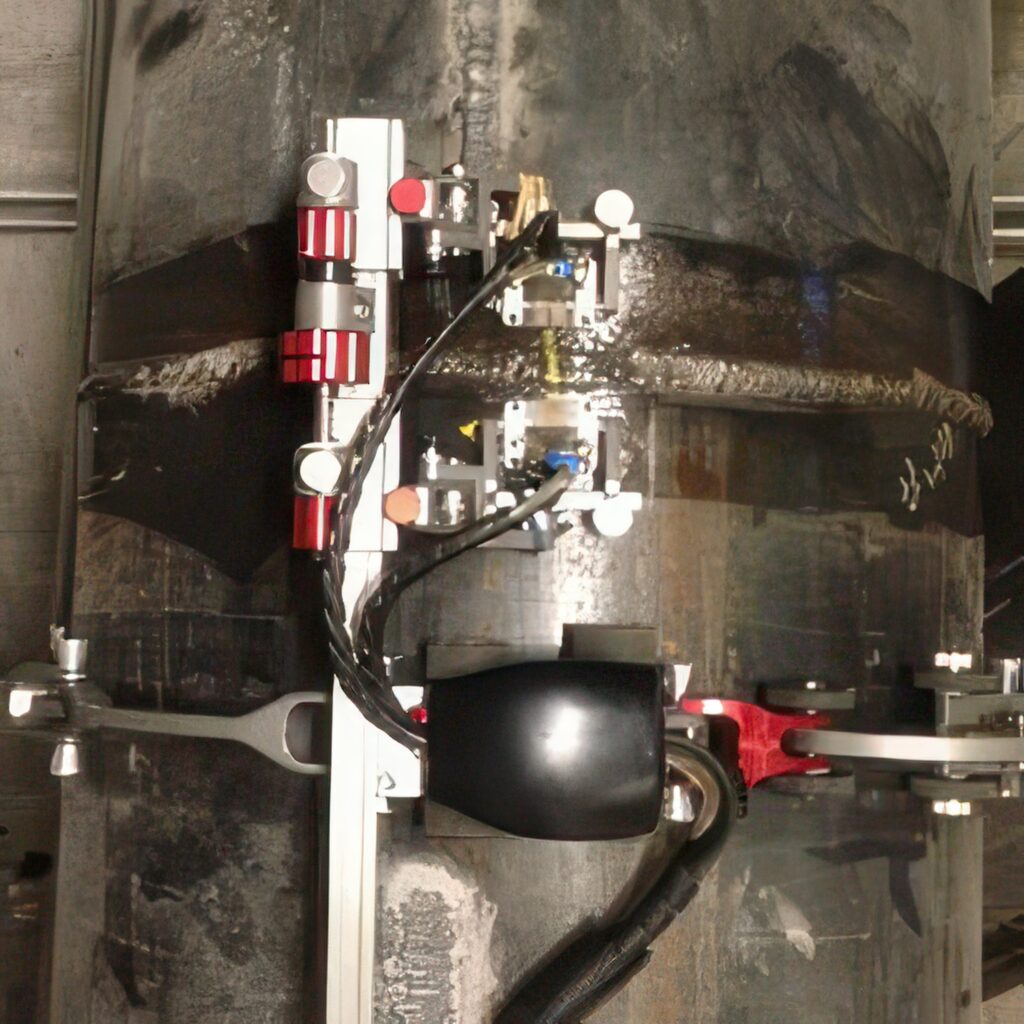

Phased Array Ultrasonics (PAUT)

Phased Array Ultrasonics (PAUT) uses multiple ultrasonic elements to electronically steer and focus sound waves, producing detailed, real-time images of internal structures. This technique is ideal for weld inspections and complex geometries, offering a high-resolution, efficient alternative to traditional radiography.

Shear Wave Ultrasonics (SWUT)

Straight Beam Ultrasonics (Corrosion Mapping)